General Motors is well known for its small-block V8 engines; especially the powerful, reliable, and versatile LS series that debuted with the C5 Corvette in 1997. Unlike most of its rivals, GM decided to use an old-fashioned OHV (overhead valve) construction, eschewing more modern SOHC and DOHC engine designs. An OHV engine has the camshaft inside the engine block and uses pushrods to operate the valves, while OHC engines have the camshaft in the cylinder head and use tappets to open and close the valves. The first LS, the LS1, produced 345 horsepower and 350 pound-feet of torque.

The LS1’s block and pistons were made from aluminum, which saved weight and helped with heat dissipation. Most LS heads are interchangeable thanks to the standard bolt pattern, giving tuners and swappers some flexibility. OHV engines can be improved with a hot cam, although you’ll have to upgrade the pushrods and valve components as well. Once this project is complete, the upgraded top end is able to handle more torque and horsepower than a stock setup. This strength is largely due to the use of six-bolt main bearing caps; four vertical and two horizontal. Most engines use two- or four-bolt configurations, which make for a weaker link between the crankshaft and connecting rods. The added strength provided by the six-bolt setup helps prevent failure under extreme tunes and high-stress operation, and the OHV architecture makes for a simpler (and more reliable) machine.

After many years of availability in GM’s lineup and as crate motors, the LS series has a loyal following. LS swaps are popular in part because of their small form factor, which frees up a little space for more displacement and performance-boosting intake and exhaust setups.

How LS engines handle so much power

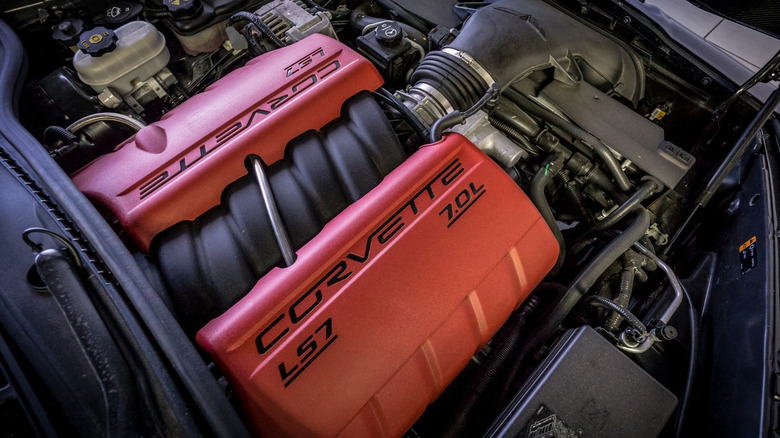

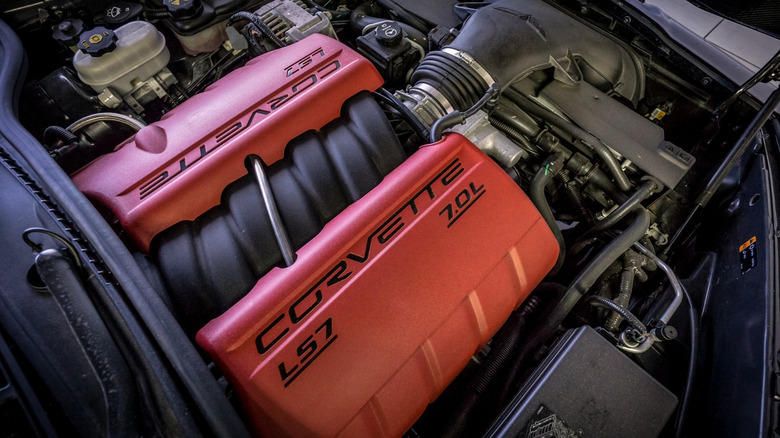

LS motors are built for serious pound-for pound power delivery right out of the factory. The LS7 found on some Corvette Z06 and Camaro Z28 models produced 505 horsepower and weighed just 454 pounds, while the supercharged 6.2-liter LS9 made an outrageous 638 horsepower and 604 pound-feet of torque straight from the factory. The LS7 and LS9 rank as two of the most powerful LS engines ever made; these engines rely on a simple design and robust construction to handle such output, and those factors make LS powerplants a tuner’s delight.

In the right hands, LS motors can generate numbers that make hypercars blush, thanks to the six-bolt bearing design. This important feature plus lightweight construction and the use of high-strength materials combine to make LS engines an ideal foundation for high-horsepower builds.

The blocks, rods, and pistons are made to withstand a lot of force. Just swapping the cam and head can boost an LS3’s output by almost 100 horsepower, and later iterations like the LS9 and LSX can produce four-figure numbers on the dynamometer. These engines can handle huge amounts of stress, and their compact design also leaves room to add forced induction. Thomson Automotive worked with GM Performance Parts to build a twin-turbo 400 cubic inch LSX engine that churned out a staggering 2,048 horsepower, proving its strength and reliability through 150 tests at full load. Thompson Automotive president Brian Thompson told Motor Trend, “We’ve never lost a head gasket or had any real issues with it … We replaced some bearings for good measure after so many dyno pulls, but the engine has been very reliable.”